Efficient Packaging Line Conveyor Weat Packing Lines Palletized Packaging Line Hot sale

1.Weat Packing Lines introduction:

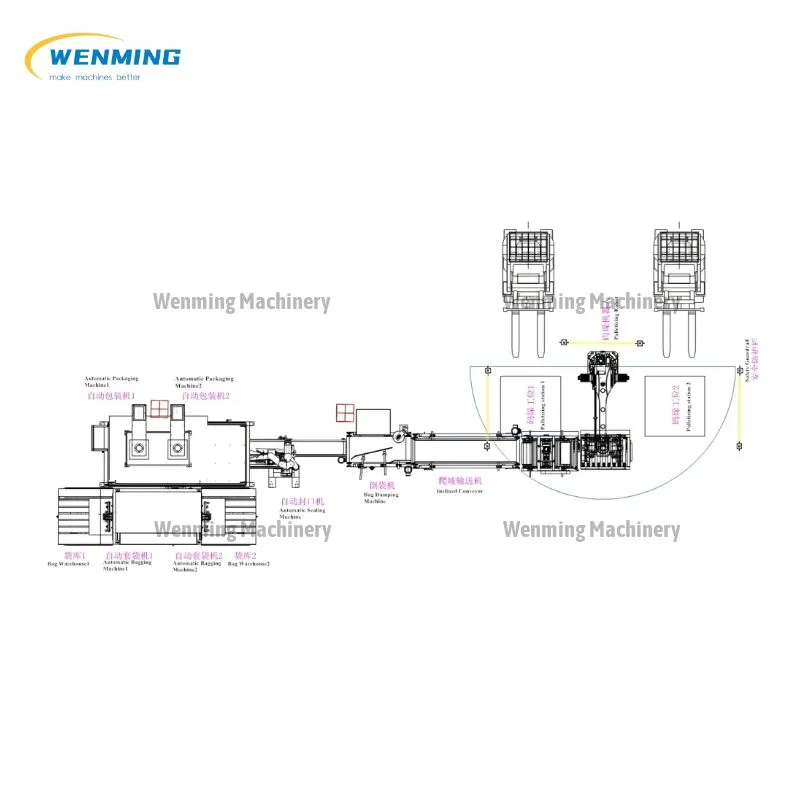

1. The automatic packaging machine system consists of: bag warehouse, automatic bagging machine, automatic packaging machine, automatic sealing machine, sealing conveyor and automatic control system.

2. The automatic palletizing machine system consists of: bag inverting conveyor, climbing conveyor, shaping conveyor, waiting conveyor, robot palletizing machine and protective device.

The automatic packaging and palletizing production line consists of 1 set of dual-machine automatic packaging machine and 1 set of automatic palletizing machine. The rated output is 600 bags per hour. The automatic packaging production line integrates automatic bagging, automatic quantitative packaging, automatic sealing, automatic bag inverting, automatic shaping and automatic palletizing. All processes are completed automatically by the equipment without the need for workers to operate.

The automatic packaging production line is a general-purpose automatic packaging production line for bulk materials that our company has improved for bulk material production enterprises based on our company's traditional automatic packaging production line equipment. This production line equipment is widely used in the automatic packaging of various types of bulk raw materials and finished products. The automatic packaging production line equipment has low requirements for the user's site, infrastructure and packaging materials. In particular, it overcomes the requirements of traditional automatic packaging machines on packaging bag materials, allowing users to use automatic packaging machines without changing the bag material, greatly saving the cost of packaging raw materials for users.

2.Weat Packing Lines Technical parameters:

| Automatic Packaging and Palletizing Production Line 300 bags/h |

|||

| NO. | Name | Quantity | Function |

| 1 | Automatic packaging machine system | 1/Set | It consists of bag warehouse , automatic bag loading machine, automatic packaging machine, automatic sealing machine, sealing conveyor and automatic control system. |

| 1.1 | Bag warehouse (automatic bag supply machine) | 2/Sets | Used: Bag warehouse (automatic bag feeding machine) is used to store empty bags and automatically feed bags to the bagging machine |

| 1.2 | Automatic bag loading machine | 2/Sets | Automatically put the bags sent from the bag warehouse flat on the bag clamping mouth |

| 1.3 | Automatic packaging machine | 1/Set | Automatically fill the material into the bag according to the weight set by the user |

| Speed:300bags/h | |||

| 1.4 | Automatic sealing machine | 1/Set | The filled packaging bags are automatically sealed. |

| Speed:10-12ags/min | |||

| 1.5 | Control system | 1/Set | Automatically control the operation of each device of the automatic packaging machine and connect it to the external network monitoring system through the port. |

| 2 | Automatic Palletizing System | 1/Set | It consists of bag dumping conveyor, climbing conveyor, shaping conveyor, waiting conveyor, robot palletizer, palletizing station, protective device, conveyor line control system and robot control system. |

| 2.1 | Package inversion conveyor | 1/Set | Place the sealed bags upright on the conveyor flatly |

| 2.2 | Inclined conveyor | 1/Set | The material in the packaging bag is leveled by the inclination angle of the climbing conveyor itself |

| 2.3 | Shaping conveyor | 1/Set | The shaping conveyor is composed of a square stick conveyor. The bags passing by are bumped by the square sticks to achieve a flat effect. This is convenient for the subsequent robot palletizer to stack evenly. |

| 2.4 | Swing conveyor | 1/Set | The palletizing conveyor adopts a stick-type conveying structure. The robot palletizer gripper safely grabs the packaging bag through the gap between the round sticks. |

| 2.5 | Palletizing Robot | 1/Set | Place the packaged woven bags neatly on the pallet according to the set procedure |

| (400bags/h) | Speed:400bags/h | ||

| 2.6 | Palletizing station | 1/Set | The robot places the packaged woven bags here. |

| 2.7 | Safety net | 1/Set | The safety fence is a device used to limit the range of motion of the robot; it is used to fix the robot's working area and restrict people from entering the robot's working area. |

| 2.8 | Robot gripper | 1/Set | The robot uses its gripper to pick up the packaged bags from the conveyor waiting for loading and place them at the corresponding position on the pallet. |

| 2.9 | Robot control system | 1/Set | Control the operation of the robot |

| 2.10 | Conveyor line control system | 1/Set | Automatically control the start/stop of the bag-reversing conveyor to the code-waiting conveyor. Self-check and alarm of conveyor status, etc. |

Contact Us to Get a Quote